Research

Research

- Planning and Coordination Division

- General Services Division

- Technology Services Division

- Dept. of Agricultural Environment

- Dept. of Agricultural Biology

- Dept. of Agro-food Safety and Crop Protection

- Dept. of Agricultural Engineering

- Dept. of Agricultural Biotechnology

- National Agrobiodiversity Center

- Research Paper

Dept. of Agricultural Engineering(농업공학부)

The Department of Agricultural Engineering is dedicated to developing advanced technologies for the future, aiming to produce agricultural products quickly, conveniently, and consistently through digitalization of the production process. We are developing technologies for the automation and robotization of agricultural work using artificial intelligence and big data. Additionally, we are conducting research on the advancement of customized upland agricultural machines to address the challenges posed by the feminization and aging of rural labor. We are also engaged in development of carbon-neutral technology using renewable energy to respond to climate change and extreme weather, research into environmental optimization of agricultural facilities, plus post-harvest quality management, storage, and distribution technology to enhance the value of agricultural and livestock products. Moreover, we are developing technology for agricultural disaster prevention to establish a stable infrastructure for agricultural production, and also working on agricultural mechanization policy technology to enhance the quality of agricultural machinery. We provide policy support through agricultural health and safety research, as well as the production of safety accident statistics, to enhance the quality of life in agricultural and rural areas.

(1) The Department of Agricultural Engineering

Consists of five divisions and is responsible for five primary tasks. These tasks include automation and robotization technology in agricultural production, renewable energy and energy-saving technology to address climate change, stable management of farm households, post-harvest quality management, and storage and distribution technology to improve the added value of agricultural products. Additionally develops preventative technology for agricultural disasters and developing customized upland agricultural machines in response to the feminization and aging of rural labor. Also, improves health and safety for farmers and seeks to reduce the agricultural workload.

(2) Smart Farm Development Division

Conducts research to respond to the demands of future agriculture, such as smart agriculture, hightech agricultural machinery, plant factories, and livestock facility automation, through convergence of artificial intelligence and IoT, big data analysis, cloud service technology, robots, and automation technology that are core technologies of the 4th industrial revolution.

(3) Energy and Environmental Engineering Division

Has been developing technologies to save energy and optimize the environment in agricultural facilities. Additionally, for low-carbon agriculture, conducts research into utilization of new and renewable energy in agriculture. Recently, research has been conducted to improve the environment of agricultural facilities to prevent the damage caused by climate change.

(4) Post-Harvest Engineering Division

Has been developing post-harvest engineering technologies to increase farmers’ incomes and provide safe and delicious agro-food to consumers. Recent research subjects are as follows:

Nondestructive measurement for the internal and external quality of food; monitoring and data acquisition system development for food processing; storage, distribution and hygiene management; storage and packaging technology to extend the shelf life of food; processing technology including washing, sterilizing, drying, aging, and fermentation; and the elemental technologies required for smart APC (agricultural product processing complex) and food factories.

(5) Safety and Disaster Prevention Engineering Division

Has been developing a virtual reality-based driving agricultural machine simulator and an IoT-based system for agricultural machine traffic safety and accident detection alarms. Is developing safe and convenient equipment and safety guidelines to prevent agricultural injuries and diseases, and providing statistics on the current status of occupational injuries and diseases among farmers. Also, by upgrading structural safety evaluation technology for agricultural facilities and improving anti-disaster design standards, makes great efforts to create a safe agricultural environment.

(6) Upland Mechanization Division

Has been developing the agricultural machinery for upland crops such as soybeans, potatoes, and garlic. Mainly conducts research into the development of seeders, transplanters, and harvesters, performance improvement, and the advancement and universalization of agricultural machinery. Furthermore, studies elemental technologies for precision farming.

(1) Smart Farm Development Division

Conducts research into the automation and robotization of farm work and precision agricultural technologies, plant factory systems to achieve constant production of plants all year around, and environmental control and automation of livestock facilities using robots and IT technologies.

1.Development of smart farm 2nd generation technology, such as disease diagnosis and intelligent greenhouse management

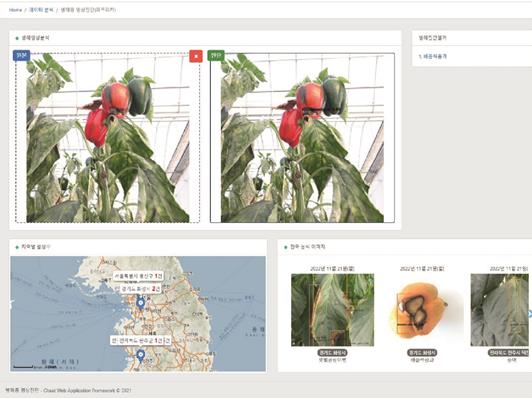

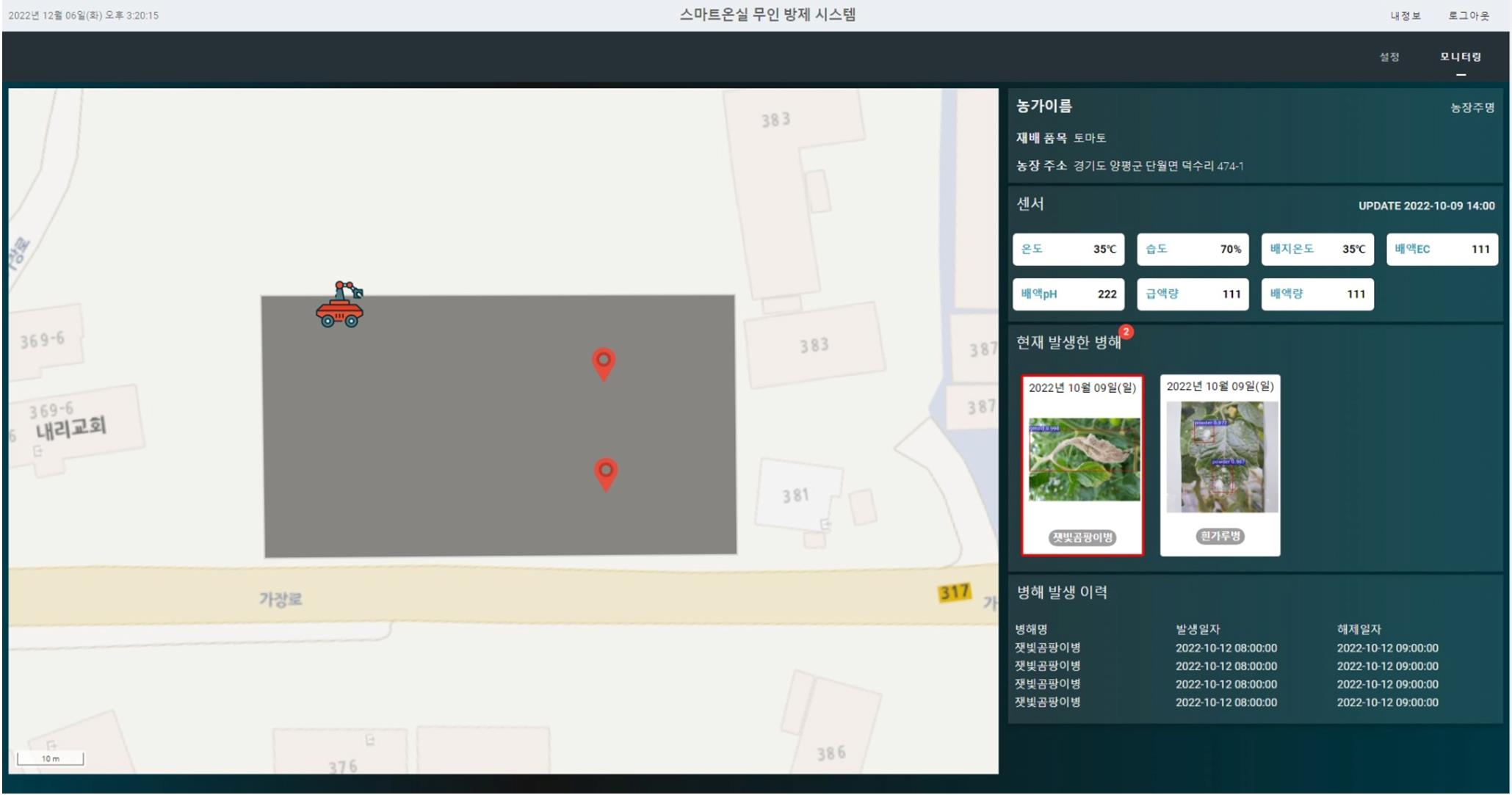

The core of the second generation smart farm is the development of automated greenhouse management technology aimed at enhancing productivity. Using artificial intelligence platforms, we are developing intelligent greenhouse management technologies that can automatically diagnose diseases and insects and physiological disorders in crops within a greenhouse periodically using monitoring robots. Disease and insect identification technology has been developed for tomatoes, strawberries, and bell peppers. It has been designed to operate on cloud platforms or Single Board Computers (SBCs). These technologies can be integrated with complex environmental controllers and pest control devices. We have developed technology that enables precise local pest control measures through automated pest management systems by utilizing precise location-based information on pest occurrences within a greenhouse. This will contribute to convenient farming.

-

<Disease and insect management>

<Disease and insect management>

-

<Location-based disease and insect information>

<Location-based disease and insect information>

-

<Monitoring robots>

<Monitoring robots>

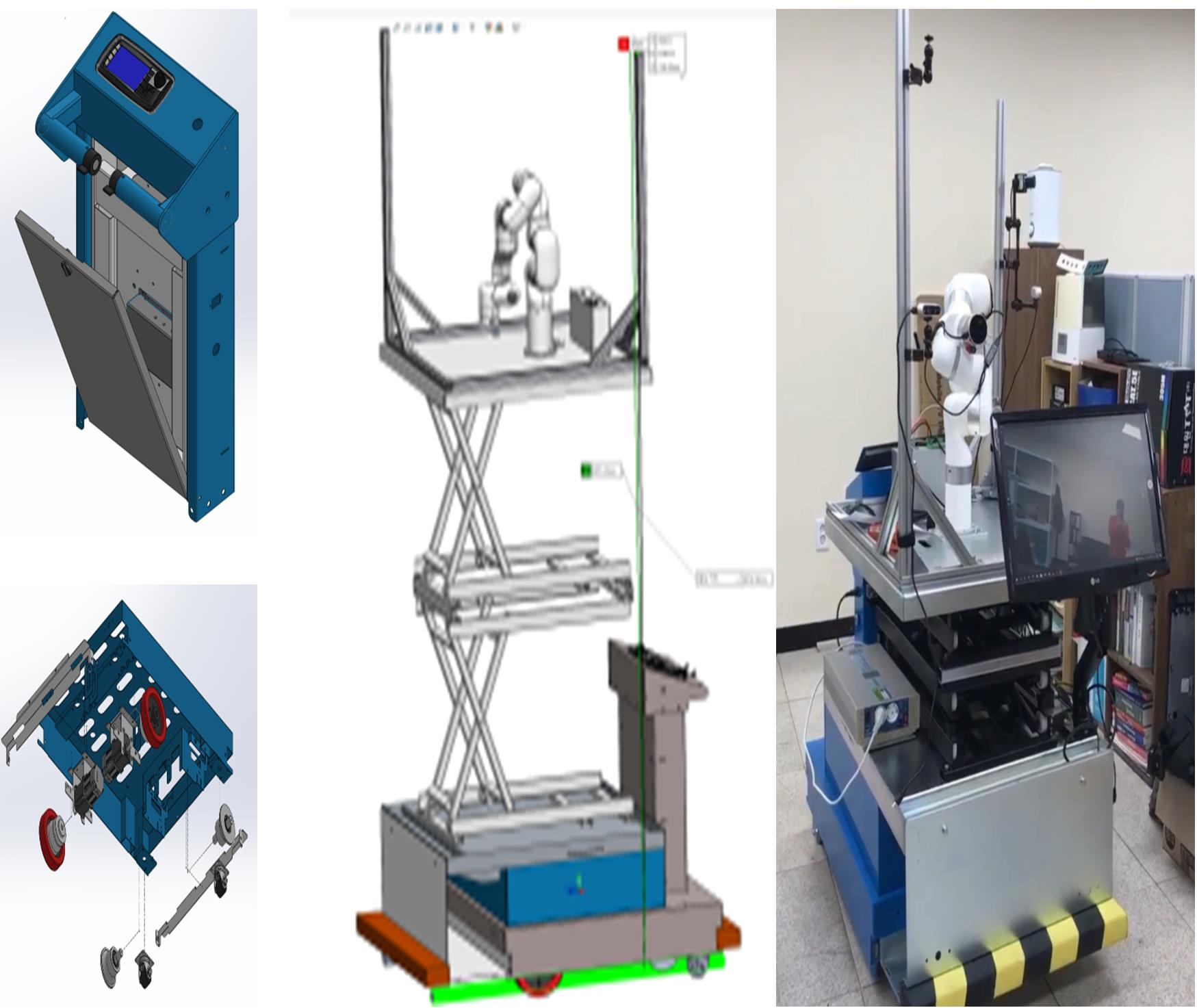

2. Agricultural greenhouse pest control robot

It is hame and repetitive that pest control task in greenhouse. In particular, safety devices for workers are necessary because they work in a closed space. For this reason, we have developed an autonomous agricultural robot for pest control tasks.

The pest control robot has a driving precision of less than 3㎝ error and a maximum working time of more than 8 hours, and it has reduced the probability of a malfunction through the SIL (Safety Integrity level) 2 controller used in the robot.

The robot is equipped with multiple sensors. It uses optical and magnetic sensors to drive the planned route, and to protect people, emergency stop sensors are attached to the front and rear of the robot.

<Autonomous traveling tractor>

3. Research on plant production systems using artificial and natural lights

Our current strategies for production-technology development include plant factories, which are facilities that aid in the steady production of high-quality fresh leaves all year round through use of artificially controlled environments (in terms of light quality, intensity, temperature, humidity, and/or culture medium) regardless of outside climate changes. Inside the plant factory, the various environmental factors are artificially controlled, and the factory can produce fresh leaves faster than in conventional field or house conditions. Am aquaponics system that integrates aquaculture and hydroponics technology has been also established as a eco-friendly farming approach through nutrient recycling without involving any chemicals for plant production.

-

<Artificial light-based plant factory>

<Artificial light-based plant factory>

-

<Aquaponics system>

<Aquaponics system>

(2) Energy and Environmental Engineering Division

consists of 3 research laboratories that are renewable energy, energy convergence, and facility environment engineering laboratories. Firstly, the renewable energy laboratory searches for the energy in new resources such as solar power, geothermal power, water power, and waste heat energy of livestock excretions. Secondly, energy convergence laboratory carries out the research focusing on agricultural facility's energy monitoring & diagnosis, improving minimum plant warming & cooling skill, and minimizing energy consumption. Lastly, facility environment engineering laboratory searches on the technique that can advance energy efficiency by using multi-variable control of micro-climate environmental factor of agricultural facilities.

We have been trying to construct an infrastructure for a green agricultural facility of "carbon neutrality" fossil energy organically cooperated with each laboratory, develop and distribute an environment-friendly energy technique in agricultural facilities.

1. Development of technology to improve crop growth in summer

The developed high-efficiency nutrient solution cooling system uses a three-way valve and buffer tank to enable precise nutrient solution temperature management with a cooling capacity of about 50% of that of a general cooling system. This cooling system has increased lettuce root vitality by 70% and yield by about 40%, despite high greenhouse temperatures exceeding 40℃ in summer.

<Advanced nutrient solution cooling system>

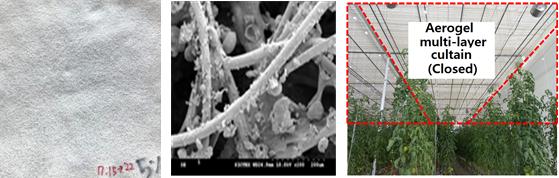

2. Development of a multi-layer insulating curtain with Silica Aerogel

We developed a multi-layer insulating curtain which improved the functionality of the existing one by using Silica Aerogel, It generates an insulating rate increase of 15~20% but is less thick and less heavy than conventional equipment. It also functions to manage the temperature and humidity inside a greenhouse properly.

<Aerogel multi-layer insulating curtain>

3. Development of a nutrient solution drainage sterilization and reuse system

We developed a nutrient solution drainage sterilization and reuse system. This is technology that sterilizes and reuses drainage produced by hydroponic cultivation using microbubbles. It sterilizes the drainage and reuses the remaining fertilizer components and water resources contained in the drainage, so it is expected to reduce the environmental load as well as reduce the production costs of farms. It is believed that a 20~30% cost reduction is possible when all normally generated drainage is processed and reused. In addition, considering that a lot of energy is invested in the production process of nutrient solution components, a reduction in carbon emissions can be expected.

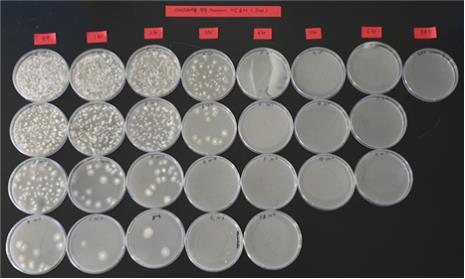

-

<Nutrient solution drainage sterilization and reuse system>

<Nutrient solution drainage sterilization and reuse system>

-

<Tomato wilt disease targe, culture after treatment>

<Tomato wilt disease targe, culture after treatment>

-

<Verification of crop cultivation by applying treatment solution over time>

<Verification of crop cultivation by applying treatment solution over time>

(3) Post-Harvest Engineering Division

Consists of 3 research laboratories comprising the cold-chain system, agro-food quality & safety sensing, and agro-food processing system. Firstly, cold-chain system laboratory develops storage, packaging and traceability technologies to extend the shelf life of agro-food. Secondly, the agro-food quality & safety sensing laboratory develops non-destructive sensing technologies that ensure the quality and safety of agricultural products in such as sugar content, freshness, and prevention of harmful substances (foodborne bacteria, pesticide residues, and heavy metals, etc). Lastly, the agro-food processing system laboratory develops processing technologies that automate labor-intensive processes and improves the added value of agro-food.

1. Controlled atmosphere and modified atmosphere technology to extend shelf life

The cold storage of agro-foods has been improved with dynamic controlled atmosphere storage offering a respiratory quotient, and pallet size-modified atmosphere package (MAP) with a sensor-based vent area control unit.

-

<Dynamic controlled atmosphere storage>

<Dynamic controlled atmosphere storage>

-

<Sensor-based control unit for MAP vent area>

<Sensor-based control unit for MAP vent area>

2. Advancement of grading technology for fruit and beef

A fruit sugar content grader and image acquisition device to identify the quality of fruit and beef meat has been improved by incorporating non-destructive optical-based imaging technology and advanced artificial intelligence technology.

-

<Fruit sugar content grader>

<Fruit sugar content grader>

-

<Image acquisition device with a smart phone for meat grading>

<Image acquisition device with a smart phone for meat grading>

3. Establishment of integrated mechanization for seed removal and pickling of stone fruits

Integrated mechanization for automatic seed removal, washing, dehydration, and pickling of plums and jujubes has been developed.

-

<Automatic seed removal machine for plums>

<Automatic seed removal machine for plums>

-

<Integrated mechanization for plum pickling>

<Integrated mechanization for plum pickling>

(4) Safety and Disaster Prevention Engineering Division

Accomplishes tasks such as policy development for agricultural mechanization, safety improvement technology for agricultural machinery and facilities, and research on smart control technology based on real-time crop and soil condition digital data for irrigation in upland farms and green houses for soil cultivation. We have conducted a variety of research activities to improve health and safety for farmers and to reduce the agricultural work load. We have been investigating health and safety hazards that affect agricultural work conditions and developed health and safety management guidelines accordingly. We have been developing ergonomic tools and personal protective equipment to improve safety and convenience during agricultural work. Also, we have been producing statistics on occupational diseases and injuries for farmers through a nationwide survey and related data analysis.

1. Development of techniques to support agricultural mechanization policy

Our operations include an agricultural machinery rental service, publication of guidelines for quality evaluations of used agricultural machinery, and improvement of agricultural machinery utilization systems, while information pertaining to agricultural machinery repair, safe application, and application costs are provided through the website. Recently, statistics on agricultural machinery utilization and farm work mechanization rate have also been produced.

<Agricultural machinery information service website>

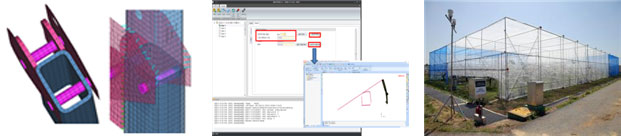

2. Development of technology to improve the safety of agricultural machinery and facilities

A roll-over protective structure (ROPS) for agricultural tractors is being tested for certification under the OECD code, and the OECD is discussing the introduction of virtual testing to reduce costs.

In order to disseminate domestic technology internationally, the standardization method and the automation program for virtual testing of ROPS has been developed. In order to prevent damage to agricultural facilities due to abnormal weather, we are developing technology to evaluate the structural safety and performance of agricultural facilities against strong wind and heavy snow and applying them to revise anti-disaster design standards. An uplift capacity test was conducted according to the depth of burial and the number of rafters for each type of soil to prepare basic design criteria for single span greenhouses (19 types) for an anti-disaster model of horticultural and herbal facilities. Three types (simple, umbrella-type, and multi-span) of improved rain shelter greenhouses were developed for jujube and peach cultivation. In addition, as a result of using insect-net facilities to reduce damage from meteorological disasters (hail, frost, heat waves, etc.) in orchards, the solar transmittance decreased by 27.2% (heat waves), and no penetration of the insect net occurred (hail), frost decreased by 46~63%, and the falling rate of fruit (typhoons) decreased by 87%.

<Standardized modeling and verification for farm facility safety>

3. Development of a smart irrigation system for upland farming and protected soil cultivation

We have developed a smart irrigation system to reduce labor and supply adequate amounts of water in a timely period. This smart irrigation system can detect water stress by sensing the soil moisture and biometric information of crops, and the timing and amount of irrigation are automatically determined using artificial intelligence (AI). When this system was applied to apple and peach trees in upland farming, crop yields increased by 19~40%, irrigation water savings were recorded at 10~31%, and water management efforts decreased by 95%. Additionally, with tomatoes on protected soil, the crop yield increased by 24% and water productivity increased by 3.2 times over that of conventional farming.

<Smart irrigation system for upland farming and protected soil cultivation>

4. Statistical research on farmers’ occupational health and safety.

We have been producing statistics on the incidence of occupational disease and injury among farmers from diverse sources including a nationwide survey and compensation insurance data from Farmer Safety Insurance. The Central Database Center has been operated, with hospital-based agricultural safety and health centers. Also, serious agricultural injury cases have been investigated and prevention strategies have been developed.

<Central Database Center and publications>

5. Agricultural work safety research

We have been developing scientific and practical products to enhance the health and safety of farmers. A digital safety management system, ergonomic tools, and personal protective equipment for agricultural work safety and convenience have been developed. Also, a website to provide agricultural health and safety information has been operated (http://farmer.rda.go.kr).

<Personal protective equipment and digital safety management system>

6. Work hazard risk assessment research

We have been conducting quantitative exposure assessment and risk assessment and providing safety standards for physical, chemical, and biological risk factors such as dust, endotoxin, pesticides, heat, ultraviolet rays, and organic gases to which agricultural workers are exposed. Also, practical safety guidelines have been developed and published based on such risk assessment of farm workplaces.

<Quantitative exposure and risk assessment>

(5) Upland Mechanization Division

Makes an effort to solve agricultural issues such as a lack of rural labor and to cope with future agricultural environment conditions through development and performance improvement of upland agricultural machinery, field adaptability improvement, and development of fundamental technologies for precision farming.

1. Development and performance improvement of field agricultural machinery

We focus on the development of seeders, transplanters, and harvesters with low mechanization rates in upland agriculture and development of complex-working agricultural machinery. We are also studying performance improvement and universalization of developed agricultural machinery, and developing advanced agricultural machinery targeted at increasing convenience for women and elderly farmers. We developed a seeder for garlic and potatoes, a transplanter for peppers and onions, and a harvester for garlic, potatoes, and Chinese cabbage. Additionally, we studied the entire process mechanization system for 10 major crops such as garlic and onions in efforts to save on labor and costs. We are also studying the complex work of upland agricultural machinery such as seeders that performs ridging, mulching, and seeding, and harvesters that performs digging, debris removal, and collection simultaneously. In addition, we are developing convenience-enhanced agricultural machinery such as auxiliary devices for attaching agricultural machinery to tractors.

-

<Garlic planter>

<Garlic planter>

-

<Potato planter>

<Potato planter>

-

<Onion transplanter>

<Onion transplanter>

-

<Potato harvester>

<Potato harvester>

-

<Auxiliary device for attaching to tractor>

<Auxiliary device for attaching to tractor>

-

<Soybean planter>

<Soybean planter>

-

<Soil disinfection machine>

<Soil disinfection machine>

-

<Grain combine>

<Grain combine>

2. Research on the improvement of field adaptability of developed machinery.

In addition, we are making efforts to improve field adaptability for developed machinery to improve the spread of upland agricultural machinery. In order to overcome the difference in cultivation techniques for crops according to varieties and regions, developed machinery is tested under various conditions so that the problems that may arise when they are distributed to agricultural sites are identified and addressed in advance.

<Field exhibition>

3. Development of fundamental technologies for precision farming.

We are developing elemental technologies to cope with future agriculture, beyond the development of simple agricultural machinery. We will develop basic technology that can support farmers' decision-making by measuring, collecting, and analyzing data generated during agricultural work such as seeding, transplanting, harvesting, pest control, fertilization, and irrigation in real time. In addition, we will develop basic and elemental technologies that can cope with future unmanned agricultural work by applying advanced technologies such as drones, autonomous driving technology, and autonomous agricultural work technology to upland agricultural machinery.

<Drone pest control>